Part 2 of a 2 Part Series on Replacement Watch Bands for the Swiss Army Hunter Watches

Last week I discussed many options for replacing the specialized watch bands for Swiss Army’s Hunter Mach 1, Mach 2 and Mach 3. Modifying pixels is easier than making things in real life, especially if you don’t have the skills, tools or knowledge to accomplish your task. But I decided to put some of my digital musings to the test, and try to build an alternate watch band for these watches. I learned some important things along the way.

Swiss Army Hunter Lug and Watch Band Measurements

First, watches are precision-made items. Duh! That goes without saying because of the mechanisms working inside the case to tell time. But, that precision manufacturing can also be applied to the watch band and how it attaches to the case. Only extreme magnification will show additional micro-engineering by watch designers that are not easily seen at arm’s length.

The majority of watch bands are attached using spring bars, which slide into the lug-end of watch bands, and the spring-loaded ends are captured by holes on the inside of the lugs. The Swiss Army Hunter watches do not use this method with the original straps but employ a long single lug pin inserted from the outside of one lug, through the watch band end-link and all the way to the lug on the other side.

The lug pins slide freely into and out of drilled holes in the lugs. They can easily fall out if no band is present.

Before my Hunter watch band replacement experiments, I thought that this lug pin was just a .98 mm x 28.18 mm piece of metal, but it is a little more than that. Close inspection reveals a small groove machined into the center of both lug pins. Presumably, each groove would line up with a protrusion inside the original watch bands so that the parts would stay locked together with a tiny amount of friction.

I mention this detail because the first thing that I noticed when trying to use materials like leather, nylon or rubber to built replacement watch bands is that the lug pin could easily slide out. This is a red flag for do-it-yourselfers who are not aware of this seemingly minor detail. If this lug pin were to slide out, the watch might fall off your wrist causing serious damage. Also, you could lose the pin. Good luck on finding a replacement. I suspect a good watchmaker could easily machine a new one with the correct tolerances, but that would be an annoyance and added expense. Swiss Army might be able to replace the pin, but that is not guaranteed since they no longer offer straps for the Hunter watches. However, there is another option.

See how easily the lug pins slide out? In this instance, I was just measuring the lug space and tilted it slightly.

During my experiments, I confirmed that that the long lug pin can be replaced with a 12 mm spring bar, which may make it safer to install traditional watch bands on the Hunter watches. The spring bar is less likely to slip out since it is pushing against the inner walls of the lugs and does not rely on the friction groove. Some bands worked better with the spring bar and others did not. At least this option is on the table and should be considered interchangeable for any of the strap replacement options.

Another detail to keep in mind is that the distance between the lug pin and the case is less than 2 mm, which would require using a thin watch band material. Extra thick leather bands or NATO straps might not fit without rubbing excessively. Then there is the placement of the drilled lug hole that would have to line up with the holes in the watch band. Now that I’ve talked about the parameters, on to the experiments…

Hard Rubber Replacement Watch Band from Donor Watch

My first attempt at modifying an existing watchband was a failure. I had a broken Swiss Legend watch that promised to be a good donor for the Hunter replacement watch band. The lug ends seemed to have similar end profiles, hole positions and relative thickness as the original Hunter watch band.

The lug ends were rigid, which made me think that the rubber was extra thick there. I thought I could simply trim the 24 mm ends down to 12 mm and stick it in the lugs. It was not that easy though.

As I started to cut the watch band to size, a plastic insert popped out of it. That was a surprise! This watch band was really 2 parts – flexible rubber encased a rigid plastic insert. The whole thing fell apart with each cut. I soon realized that there was no longer anything holding this watch band together, and I abandoned this option. Let’s call this one a FAILURE!!!

Velcro Replacement Watch Band

Next, I tried a different approach. I found a cheap Timex Expedition watch band that was essentially a velcro strap with a stretchy elastic attachment sewn on top. With a little bit of pushing, I was able to force the elastic under the Hunter’s lug pin and attach the watch. Even though the elastic was wider than the 12 mm lug space, it was flexible enough to conform.

This option actually worked and gave the Hunter Mach 2 a sporty, dressed-down appearance. I’m not going to say that I think it is the best look because the shape of the case does not necessarily flow with the watch band, but it would work in a pinch.

Warning… hairy arm photos beyond this point. I refuse to shave my arms for wrist shots… and besides, I don’t want to be confused with other watch bloggers who do. You know who you are… ha ha

The new watch band was extremely comfortable because it could be sized exactly for any wrist. This is the advantage over a watch band that is sized using holes. While you might be able to get close to the right size, the adjustments are less finite.

The shape of the case is revealed in the photo below. The case is a barrel shape, the lugs taper and also have an undercut angle. This cannot be seen from above, but it is there. It makes fitting a flat watch band incongruous.

There is an advantage to this type of watch band. If one spring bar or lug pin fell out, the other side should stay attached saving the watch from a fall. Any watch strap with this kind of construction should work as a Hunter watch band replacement. I am going to label this experiment a SUCCESS with caution!!!

Soft Rubber Replacement Watch Band

The next test involved a rubber Tsovet watch band. I bought a stack of these when they were only $10 each on Tsovet.com. I have to admit that these watch bands look great with the olive color and beveled edges. The hardware options are excellent and come in brushed, polished and bead blasted steel.

The down side is that these Tsovet watch bands have the most rigid rubber I have ever experienced, and that limits wearability. They are so stiff that the watch floats half and inch or so off my wrist. Tightening it only makes the sides grip harder. Ouch! My buddy who bought the same straps had a similar wearing experience. You may get different results so I am not dissuading you from buying them. Anyway, I had no problem cutting these unused rubber straps in pursuit of science.

All I had to do was measure 12 mm in the center and cut the excess rubber off of the lug ends. It was fast and easy to do. Inserting the pin through the case and the band could be performed by a simpleton… perfect. The lug pin was easier to use in this case.

The results of a Victorinox Swiss Army Hunter Mach 2 on a customized Tsovet green rubber diver’s watch band.

The look of the resulting combination was surprisingly stunning. The olive drab diver’s watch band gave the Hunter Mach 2 a bit of a military character. I really liked it from when looking from above.

The color of the new watch band added to the military-inspired design of the Swiss Army Hunter Mach 2 Chrono.

I noticed that my cuts were a rough looking and I probably should have taken greater care in slicing the rubber strap straighter. Mine were wonky. They could be cut at an angle the hides the gap when worn, but I only had one strap to experiment with.

It’s not visually perfect, but the results prove this Tsovet watch band could work on a Victorinox Swiss Army Hunter watch.

To improve on this design, I would probably find a metal spring bar sleeve and insert it into the rubber lug end. The rubber by itself works, but a little reinforcement would do wonders for stability. It should theoretically stop the rubber from twisting and flexing that might eventually lead to a tear.

Remember me mentioning these Tsovet straps were so rigid that they make my watch hover over my wrist? You can see this in the image below. That is almost 1/2 an inch above my skin. I’ll label this one as a SUCCESS with some room for improvement in my cuts!!!

Nylon 2-Piece Replacement Watch Bands

Nylon watch bands are cheap and plentiful. You can get them for as cheap as $4 shipped from China, like I did for this Infantry band. I am partial to orange, black and silver. I think this classic combination looks great together.

Nylon watch bands are cheap and plentiful. You can get them for as cheap as $4 shipped from China like I did for this Infantry band. I am partial to orange, black, and silver. I think this classic combination looks great together.

Victorinox Swiss Army Hunter Mach 2 with a cheap Infantry brand strap. These are great for just a few bucks.

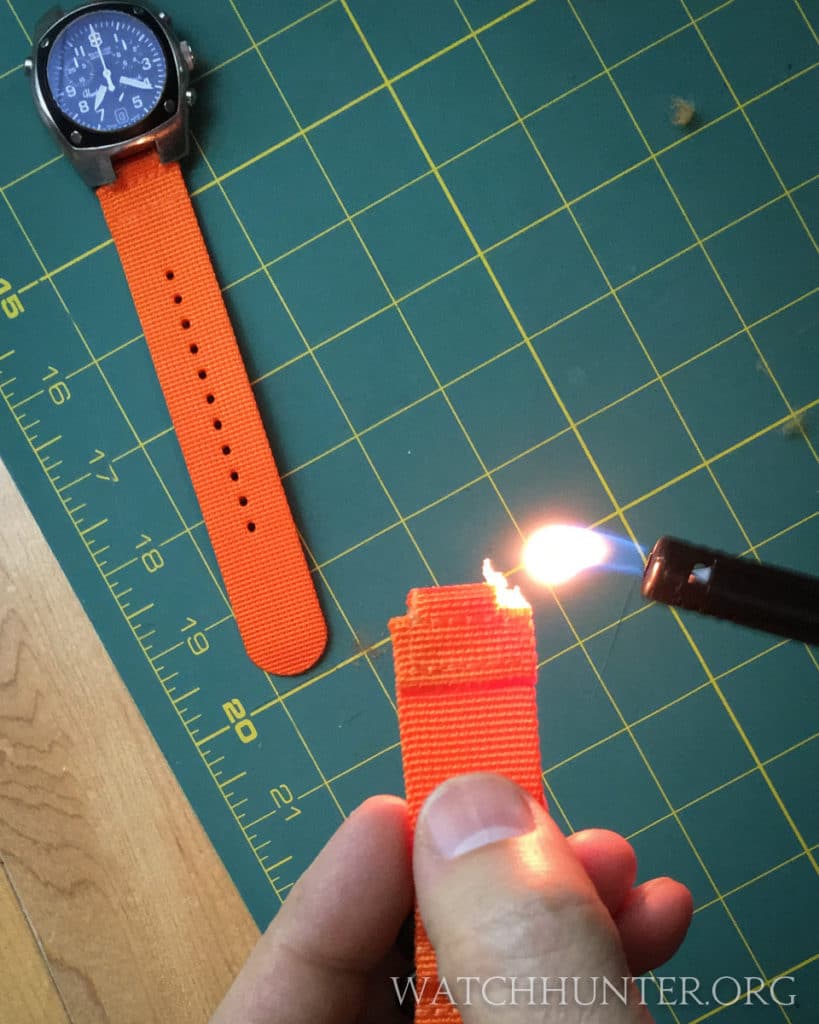

Nylon watch bands like these are usually heat-treated to prevent fraying. Be prepared to deal with some unraveling when you start cutting the lug ends to size. I tried 2 different techniques to see which worked better. The first tool that I used was a sharp set of clippers. The cuts resulted in a lot of fuzzy scraps.

The second method used a sharp razor knife and the results were cleaner, but not completely free of fuzz. The edges would have to be fixed before installation.

I suspect the these are made by the thousands in some factory in China using lasers or heated cutters that cut and seal the edge at the same time. I used something way more low-tech than that… a flame which melts the fuzz and seals the edges. It can be hard to control and you could end up with black soot and blobby ends. I’m sure that practice could make perfect. It was okay for this prototype.

The results are pretty cool, though a bit hand-made looking. I know I could do a better job with a heated wire cutter or better finishing techniques, but this is a prototype to test how these watch bands might look in the real world. I’ll just let the photos speak for themselves.

My final tip about these nylon watch bands is that you should never get lazy when using a flame to seal the ends. I tried to melt a few remainimg frayed ends while it was still on my wrist and singed a few arm hairs in the process. You don’t want to smell that so don’t be an idiot like me. ha ha. I will label this option a SUCCESS but needs improvement.

Leather Replacement Watch Band

The last material on my experiment list was leather. I was reluctant to cut factory-made leather watch bands that I have because those darn things can get expensive. However, I had a few homemade Horween straps in my parts drawer that were doing nothing so, they felt the sting of my razor instead. Sorry, little guys. The process is the same as the others… measure, cut and insert.

Small snips cleanly cut the leather watch band for the Victorinox Swiss Army Hunter Mach 2 Chronograph.

I wonder if Swiss Army would consider re-releasing this family of Hunter watches with strap options?

Of all the options, this competed with the original watch band in terms of visual appeal. It really made my Swiss Army Hunter watch look like a classic, high-end aviator watch, but judge for yourself. The biggest takeaway from this set of experiments is that I know my limitations when hand-crafting watch bands. While a few of these options show promise, better manufacturing techniques, tools or hand skills would need to be employed to make a replacement for the excellent Swiss Army original watch bands. I know someone out there has done it, so send in those photos if you made a cool replacement watch band for your Swiss Army Hunter watches.